Solar manufacturers are working towards making efficient solar panels using new technologies. This result is to understand Monocrystalline vs Polycrystalline solar panels.

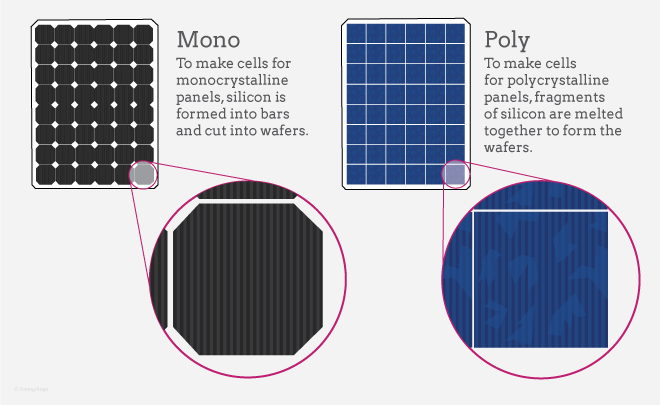

Monocrystalline solar panels comprise of silicon as a single crystal. On the other hand, Polycrystalline panels are included in many fragments of silicon melted together.

The solar panels, Monocrystalline and Polycrystalline are both important. However, it is for you to decide on a good brand.

Buying a solar panel of good brands means the manufacturing process ensures quality investment, and it does best to maintain its reputation. Both solar cells, Monocrystalline, and Polycrystalline are identical in performance.

The solar panels can be considered to be the best, taking into consideration the performance. They should have no defects and if any, the company should accept to replace the panels.

Contents

Monocrystalline vs Polycrystalline Solar Panels: A to Z Comparisons

What are the Monocrystalline Solar Panels?

Monocrystalline cells are from a single silicon crystal. It is created from a cylindrical ingot of silicon that is sliced to form wafer cells. The cell utility is maximized, while the wafers are cut into octagonal-shape wafers.

These solar cells composition is purer, and these mono panels are efficient as each cell is from a single silicon piece. They have a uniform color. They perform well in ideal conditions and varying environments.

Mono panels are expensive as there is more waste in the manufacturing process.

What are the Polycrystalline Solar Cells?

Polycrystalline cells comprise an association of multiple silicon pieces bound together. The silicon bits are treated by molding to create solar cells. The wastage is less in this process, and the reason is that the raw material is eliminated in the manufacturing process.

Most of the solar cells present a blend of giving a blue color. However, the color and texture appear uneven as it depends on the way the cells are made.

Polycrystalline panels are a bit less efficient to the former, mono panels and this is due to the solar cells surface imperfections. Manufacturing is cheaper, and so are at affordable prices, benefitting the end-user.

Monocrystalline Solar Panel Features

Monocrystalline solar panels are prominent for its features such as:

- The solar cells here exhibit photovoltaic properties and are regarded to be superior to others.

- The cells present a pyramid pattern in the panel providing a larger surface area that the sun rays energy is collected in more.

Phosphorous is used to diffuse the top surface and it assists in creating electrically negative orientation, while a positive electrical orientation is at the bottom assisting to create an electric field.

This helps in:

- Collecting the produced electricity onto the cells through metal conductors.

- Cells feature silicon nitride coating that it helps in increasing absorption and reducing reflection.

All these salient features of Monocrystalline solar panels, ensure solar energy best conversion assuring higher efficiency of electric energy. Thus, it helps:

- The panels longevity for around d 3 decades.

- Exhibit heat resistance.

Polycrystalline Solar Panel Features

Polycrystalline solar panels are popular for its features such as:

- Polycrystalline solar panels are regarded to be reliable panels.

- It is less expensive and is blueish. The solar panels are thin films.

- These solar panels’ life span is for 25 years. They bear sunlight or heat at a high level.

These solar panels are eco-friendly and the beneficial feature is that:

- They require no individual placement and shaping of crystal. This is because, during the production of the Polycrystalline panels, silicon is used.

- Thus, there is minimal waste.

Polycrystalline solar panels feature lower efficiency and lower heat tolerance:

- It features higher temperature coefficient panels.

- They are in a structural frame that mounting is simpler and cost-effective.

Differences Between Monocrystalline vs Polycrystalline

Outline

Monocrystalline is known as the solar panels having single silicon crystalline.

- It is manufactured using a continuous single crystal structure. Monocrystalline is the most developed technology.

- Polycrystalline is the combination of many silicon crystalline pieces. This is a new technology, with a different manufacturing process.

Appearance

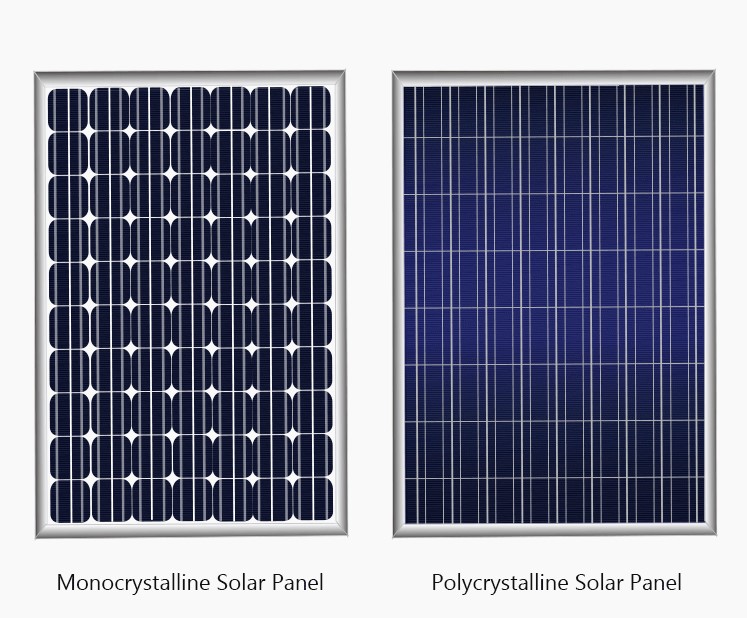

- It has a dark black external color, making it easily identifiable. The color appears as a flat single color. The material composition and shape are different. Monocrystalline panels are from one silicon crystal. The black color is because the Monocrystalline panel absorb sunlight effectively

- It is blue. Polycrystalline panels’ material composition includes multiple crystals of silicon. Their solar panels feature thin film. The color is determined by the interaction of the sunlight with a solar cell. As it has multiple crystals, it has a shiny blue color appearance

Construction

- A Czochralski method is used where a silicon seed is drawn up into a solid structure referred to as an ingot. This is sliced finely as silicon wafers and is transformed into a cell. The original silicon ends as waste in significant amounts.

- Polycrystalline begins as the silicon seed is transformed into molten silicon vat and is cooled. This gives grains and distinctive edges in the solar cell.

Cost

- Monocrystalline solar cells are highly efficient and regarded to be superior. They are expensive as they involve a large manufacturing process and lots of wastage. The installation bill is also expensive.

- Polycrystalline cells are slightly less efficient and are regarded as inferior. They are cheaper as their manufacturing process is simple and includes no wastage that they dominate the residential market as solar panels. The installation is simple and so is the cost, affordable.

Efficiency

- Monocrystalline solar cells are at a 15-20% high-efficiency level, requiring less space. They enjoy a longer lifespan of 25 years. They perform well even in low sunlight levels.

- Polycrystalline solar cells have lower heat tolerance and they perform less in high temperatures, and so the efficiency level is lesser than Monocrystalline. Their lifespan is shortened and the effect is minor.

Space

- Monocrystalline panels can work in limited space as they are highly efficient.

- Polycrystalline panels require more space as energy output is not covered.

Climate

- Monocrystalline panels are suitable for a hotter climate as they are heat tolerant. The Monocrystalline cells have ordered crystal structure that the electric current travels with ease.

- Polycrystalline panels have less heat tolerance and hence the lifespan is reduced. The cells of Polycrystalline have divisions in the structure causing the electric current slight disruption, resulting in lower efficiency.

Which is Better Between Monocrystalline and Polycrystalline

Monocrystalline solar panels are known for their higher efficiency. This does not indicate anywhere that Polycrystalline panels are of lower quality.

The material properties determine the efficiency of the solar cells and it must not be concluded as product quality indicator. If the solar panels are of top brands, both are subjected to maintain their quality standards.

Comparing the solar panels is the same as you compare a sedan and an SUV. Both are high-quality cars, yet a compact car offers better mileage due to its lesser weight.

As both solar panel types are of high quality, return on investment can be excellent as anticipated by the types of panel chosen.

Eventually, buying a good product should be confirmed and ensure the manufacture is around available, in case there is a need to check with the warranty claim.

Monocrystalline vs Polycrystalline solar panels have their specific good features. Their advantages are found suitable in different applications.

- Monocrystalline panels produce more electricity. They are more efficient and are popular in urban and rural areas featuring solar rooftops.

- Monocrystalline panels are suitable for large scale solar applications such as uncultivable land vast tracts.

- They are also suitable for commercial and residential applications. The smaller panels are useful for charging laptops, cameras, and phones as it generates electricity between 5-25W.

- It is also suitable for high wattage appliances such as microwave ovens and refrigerators generating between 40- 130W.

- They are ideal for lighting up gardens, power rural homes, and as stand-alone panels or for street lighting.

The Polycrystalline application shares its advantages:

- Polycrystalline panels are used in solar large farms to harness solar power and to supply to the nearby areas the electricity.

- They are ideal choices as roof-mounted arrays.

- They can be useful for self-powered devices such as remote areas traffic lights, or standalone off-grid households.

Comparing Monocrystalline vs Polycrystalline panels quality is simple. Assuming the available space, both work well. Yet the best option is Monocrystalline under the conditions:

- If the space is limited for solar panels.

- When generating maximum electricity is the priority.

With the restriction of space, producing more electricity is not possible for your solar system. The production is maximum in the space available with monocrystalline panels.

Believing there is no limitation of space indicates use any solar panel type. Get from multiple companies quotes and consider buying the one that offers a quick payback period and high investment return.

In case you plan to use the solar panels as per the available roof area, you can generate in surplus in the noon. Thus, the electricity that is in extra and is not consumed, is sent back to the power grid.

Polycrystalline vs Monocrystalline Solar Panel: Which is the Best!

This is viable or not is based on the way the utility company offers credit. If you fill with Monocrystalline solar panels your roof, there will be surplus production.

- Other power companies will purchase the surplus generation of electricity through your solar system at retail prices.

- On the other hand, the other power companies may take every kilowatt-hour sent by your solar panels to their grid by giving only partial credit.

In case the local power company offers for surplus generation full credit, there is a sense of getting your rooftop filled with Monocrystalline solar panels that assure you to maximize production.

However, if you are managing to receive only partial credit, it is best to take advantage of using the Polycrystalline panels that are low in price and to enjoy the benefit.

Eventually, in the month-end, the balance gets deducted in your favor from your utility bills. Thus, on producing extra electricity, you also have the opportunity to bring the utility bill to zero.

In case you receive more, the balance excesses your bill, then the difference will be taken to the next month as balance carried forward. If you are fortunate, some companies may agree to pay you in cash, but it is rare and hard to believe.

Conclusion

Monocrystalline vs Polycrystalline a continuous debate and is also a common query among buyers. There are advantages and disadvantages to these panels. The concern is on the energy output efficiency, space efficiency, and cost.

No one technology can be pronounced as superior or inferior. They both have well-matched pretty designs. The solar panel type is chosen as per the location needs, though both panels offer around the 25-year warranty.

For instance, Monocrystalline panels perform even if there are low light conditions and are effective in warm weather. Thus, for a less hot region choosing Monocrystalline will ensure the power needs are met.

While, if your budget is lower and you are in a hotter climate, the Polycrystalline is suitable as it works with the desired available energy and the cost.